Have a question? 06 70 73 89 02

🔞 Not for sale to under 18s

⏱️ 48-HOUR FLASH SALE: 20% off EVERYTHING on the site with the code FLASH 💥 ( excluding accessories and gummies)

Have a question? 06 70 73 89 02

Today we're going to talk about a revolutionary new drying method:Freeze Drying.

Like new concentrates such as CRD, or Rosin, a 100% natural extraction, Freeze Drying is a recent innovation. We make no secret of the fact that we've really fallen in love with this technique. Want to know why? Follow the article, we'll explain!

This technique is a version of freeze-drying developed in the United States specifically for hemp and Cannabis flowers. It involves cryogenically drying frozen flowers. Here's how it works:

Hemp flowers are hand-picked and placed directly into a freezing chamber. Carefully arranged, they are exposed to temperatures set between -30 and -35 degrees, for around 10 hours.

This ultra-fast freezing process freezes the water inside the flower , preserving its shape and integrity.

Once the water inside the flowers is frozen, the pressure inside the chamber drops rapidly. A vacuum is created, triggering the sublimation process.

This process refers to the passage of a material from a solid state to a gaseous state without passing through the liquid stage. The ice inside flowers is thus converted to steam without having become water in the meantime.

The steam in the tank then takes the opposite route, condensing and refreezing in a special compartment.

Of course, in this ice, there's also a tiny fraction of terpenes that were carried away by the vapor during sublimation. These are recovered at the end of the process for reuse in e-liquids or oils.

The entire process takes 24 hours. After just one day, the moisture is extracted from the flowers and they are ready to eat.

The process is very quick and quite spectacular in itself. But it's not just the beauty of the gesture that's of interest: the result is simply incredible. Everything changes for the better: appearance, taste, smell, texture, even potency!

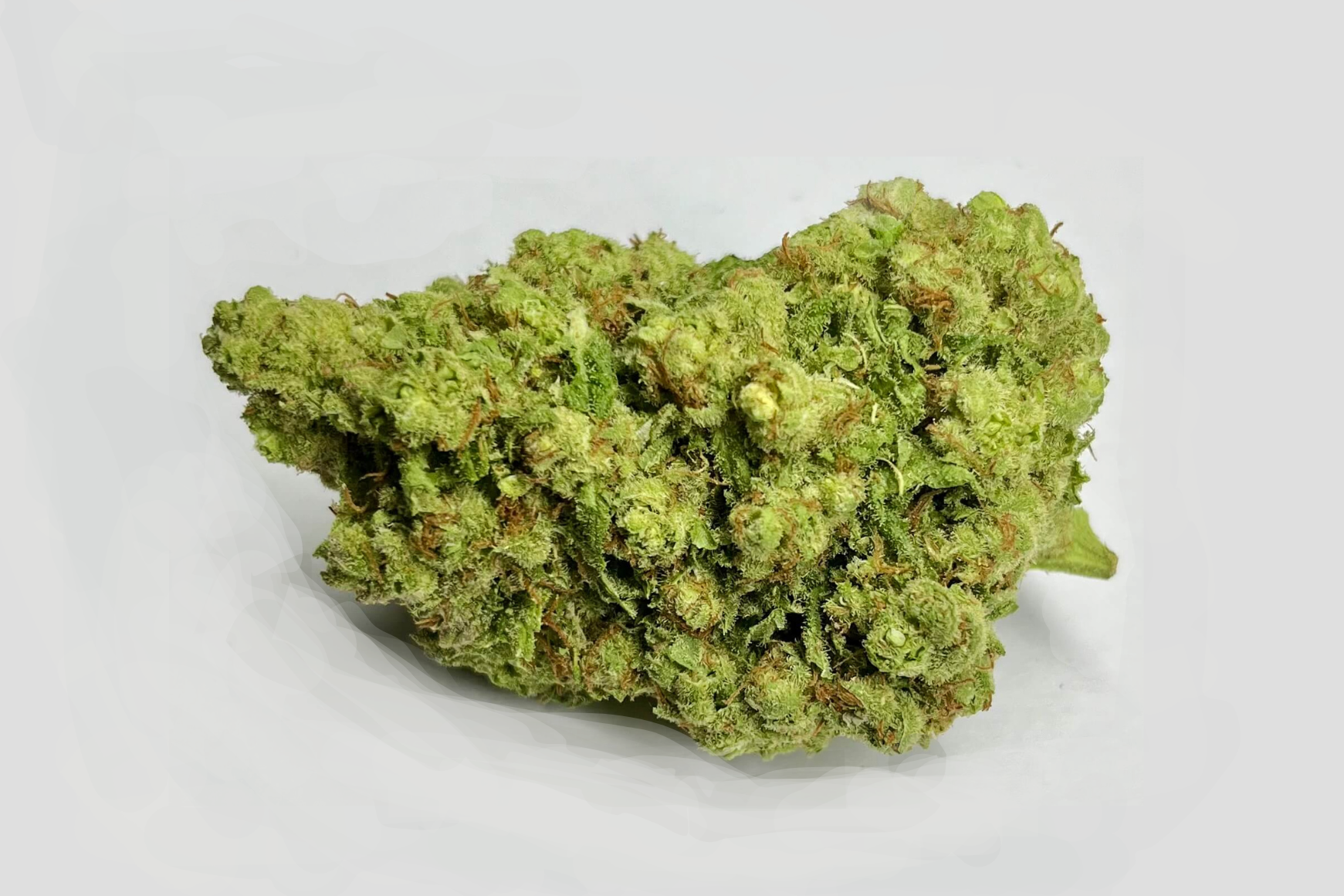

The flowers, frozen and dried directly after picking, retain their vibrant green appearance and are covered in a beautiful, glistening trichome coat.

But it gets even better: they're slightly inflated, as light as a feather. In other words, they offer a lot of volume for very little weight. At 1 gram, you feel like you're looking at 4!

As we've just said, the flowers are slightly swollen, the vacuum during the process gives them a cottony texture, and they contain just the right amount of moisture to hold together and provide the best possible eating experience. They crumble with just the touch of a finger.

According to some reviews, this perfect humidity level makes vaping lighter and all the more pleasant.

In terms of taste and smell, it's an experience that no other flower can offer, and one that can only be found in L'ice-o-lator: the experience of consuming fresh flowers. The fact that they have been dried as well as frozen preserves an immaculate terpene profile, including terpenes that are normally lost during drying.

Let's talk about what interests many of us: potency. Here again, as you'll have gathered, a much greater portion of the cannabinoids and terpenes originally present are preserved, increasing the final potency. During the drying process, certain terpenes and cannabinoids oxidize and are lost, lowering the final potency. Thanks to Freeze Drying, all the basic compounds are fully preserved, just like in a living flower.

According to our research, the history of Frozen Weed began with Ed Rosenthal, one of the leading figures in the U.S. cannabic movement.

In the 70s and 80s, he came up with the idea of using the freeze-drying process conventionally used in the food industry to reduce the moisture content of flowers. The technique preserves the flowers longer and reduces the risk of fungal growth. But the technique is not without its advantages. One problem is that freeze-drying is quite aggressive, making the flowers very crumbly and brittle.

Based on this observation, two other Americans, Greg Baughman and Tracee McAfee, set to work to advance the technique and adapt it to flower drying. By adapting the containers to the size of the heads, and adjusting the drying process to achieve the optimum moisture content for the plants, their technology revolutionized flower drying, resulting in an entirely new product. The product then spread to American dispensaries, delighting consumers.

With the progressive legalization of hemp throughout the world, research and discussion about hemp can proceed freely. Extraction, cultivation, drying and curring techniques continue to develop. New, ever more innovative products are emerging. These more plant-friendly processes give rise to unique consumer experiences. We're still waiting for a moonrock to be composed from these flowers, and we'll be sure to keep you informed!

Cryogenic drying is still in its infancy, but its popularity is growing all the time, and we see a very bright future for this technology. That's why we're very proud to be able to offer you one of the first flowers of this type available in France, and we hope you'll like it as much as we do. And if you do, keep up to date with CBD news on our blog!